Process Description

The SPM-2100 Continuous Stirred Tank Reactor (CSTR) Process Simulation can be configured to react any two gases. The reaction can be exothermic or endothermic. The default configuration reacts ethylene (reactant A) with benzene (reactant B), an exothermic reaction, to produce ethylbenzene (product C), an intermediate chemical used in the manufacture of styrene monomer. There are no side or competing reactions simulated.

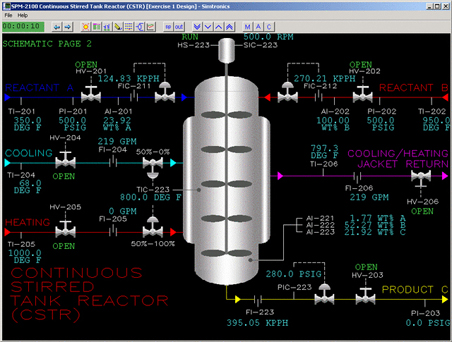

Reactants A and B are fed to the Continuous Stirred Tank Reactor (CSTR) where they are completely mixed with a motorized agitator.

Reactant A feedstock is assumed to come from a typical refinery FCC. Consequently, there is a substantial concentration of inerts in the feed. Since the reaction is highly exothermic, the inerts serve to dilute the feed and aid in preventing a reactor run-away.

Reactant B feedstock is assumed to be of the highest available industrial grade and is therefore effectively 100% pure for the purposes of this simulation.

The reactor is sized to convert most of reactant A to product. The feed molar ratio of reactant B to reactant A is maintained at 3.25 to 1.

The product stream is purified downstream of the reactor through a

series of distillation columns. The inerts are vented, recompressed, and

used as a fuel gas elsewhere in the plant. Reactant B is recovered,

purified, and recycled back to the reactor. The purification of the

product stream is outside the scope of this simulation.

Instrumentation

The reactant A feed flow loop is outfitted with a composition analyzer (AI-201) that measures weight percent A, the balance being inerts. The supply temperature and pressure are indicated by TI-201 and PI-201 respectively. The feed block valve can be opened and closed with switch HV-201. Reactant A flow to the reactor is modulated by flow controller FIC-211.

The reactant B feed flow loop is outfitted with a composition analyzer (AI-202) that measures weight percent B, the balance being inerts. The supply temperature and pressure are indicated by TI-202 and PI-202 respectively. The feed block valve can be opened and closed with switch HV-202. Reactant B flow to the reactor is modulated by flow controller FIC-212.

The reactor contents are mixed by a motorized agitator which can be turned on and off with switch HS-223 and whose speed can be controlled with SIC-223.

Reactor temperature is indicated by TIC-223 which controls the reactor temperature by modulating the cooling and heating flows to the reactor jacket, indicated by FI-204 and FI-205 respectively. Total flow through the reactor jacket is indicated by FI-206. Cooling flow inlet temperature is indicated by TI-204, heating flow inlet temperature is indicated by TI-205, and reactor jacket outlet flow temperature is indicated by TI-206. The cooling flow block valve can be opened close with switch HV-204, the heating flow block valve can be opened and closed with switch HV-205, and the reactor jacket effluent block valve can be opened and closed with switch HV-206.

Reactor pressure is controlled by PIC-223 which modulates the reactor effluent flow, indicated by FI-223. The reactor effluent block valve can be opened and closed with switch HV-203. Product discharge pressure is indicated by PI-203.

Reactor compositions are indicated by AI-221 (WT% A), AI-222 (WT% B), and AI-223 (WT% C). Inerts compositions can be determined by difference.