Process Description

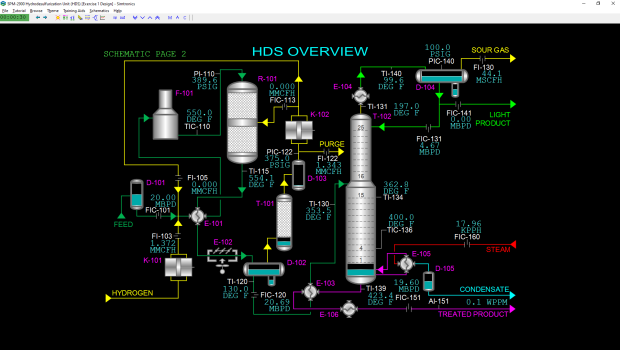

Simtronics’ Renewable Diesel Hydrotreater catalytically converts a mixture of plant-derived oils to an environmentally-friendly diesel fuel suitable for use in transportation (so-called biodiesel). Plant-derived oils are of high molecular weight and contain consist of a high amount of oxygen in the oil molecules. This makes them unsuitable as a transportation fuel in diesel engines. The Renewable Diesel Hydrotreater process is similar to a conventional fuels hydrotreater found in the crude oil refining industry with a few key differences. The Renewable Diesel Hydrotreater uses higher pressures and temperatures to react feed oils with makeup and recycled hydrogen over 8 catalyst beds operating in series. The hydrotreating reactions, particularly the conversion of the oxygen in the feed oil to water, release large amounts of heat. Therefore, the feed is distributed to the first three reactor beds so as to limit the temperature rise in those beds. In the subsequent catalyst beds, cool recycle gas, rich in hydrogen, is used to quench the hot reactor outlet streams leaving the upstream beds. To ensure nearly all the feed oil is converted in the process, a large portion of the liquid produced from the reactors is recycled back through the reactors. The rate of recycle is normally equal to the rate of the fresh feed to the unit on a volume basis.

The reactor beds also convert some of the plant-based oils to hydrocarbons lighter than diesel, such as naphtha (gasoline) and light hydrocarbons (butane, propane ethane and methane). These lighter components must be stripped from the liquid produced by the reactors before the biodiesel can meet diesel engine fuel specifications. The Renewable Diesel Hydrotreater also includes a Stripper column to separate these lighter components from the biodiesel prior to sending the product storage. These lighter components are recovered in the overhead system of the Stripper.

A full range of operations can be practiced and mastered on the Renewable Diesel Hydrotreater simulator including startup, planned shutdown, emergency shutdown and equipment/instrumentation troubleshooting and recovery. Feed oil properties, such as the oxygen content and the heat of reaction, can be modified to set up operating conditions and scenarios representing a wide range of feed oil types. The Renewable Diesel Hydrotreater simulator includes a rich set of faults for all simulated instruments and equipment to create realistic and challenging operating scenarios.