Process Description

Simtronics Potable Water Plant simulator replicates a typical process for producing drinking water for municipal distribution.

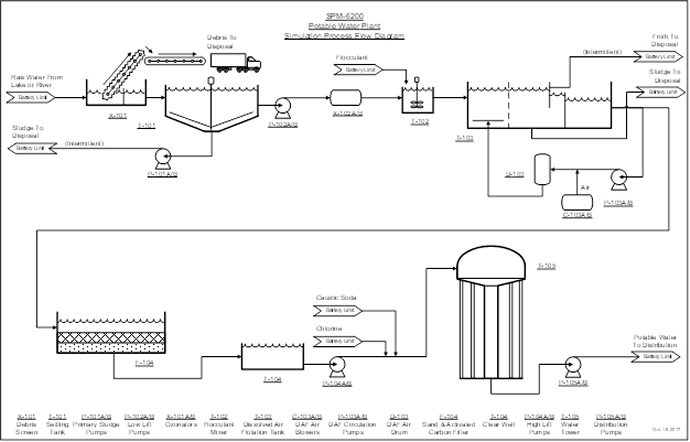

Raw water taken from a surface source such as a lake or river flows by gravity to the debris screen. Coarse filters remove debris and large objects from the raw water prior to entering the settling tank. The debris is collected and sent off to a landfill for disposal. The raw water flows over a weir into the collection compartment of the debris screen.

Raw water flows by gravity from the debris screen to the settling tank. Any sludge settles to the bottom of the settling tank and is removed by pumping to disposal. Settled raw water from this large, open tank is pumped by the low lift pumps to the ozonators where it is mixed with ozone produced by ozone generators. Ozone is a strong oxidizer and, therefore, disinfects the water by quickly attacking many bacterial agents in the raw water.

The disinfected water from the ozonators flows into the flocculant mixer where flocculants and other chemicals and agents are added and finely dispersed into the water by strong agitation. These additives promote coagulation of smaller particles, including the inert byproducts from ozonation, into larger particles. The flocculated water continues on by gravity to the dissolved air flotation tank.

The dissolved air flotation (DAF) tank removes suspended solids and immiscible oils remaining in the water after the flocculation mixer using a circulating stream of air-saturated water. These undesirables are lifted to the top of the DAF tank by small bubbles of air released from the circulating air-saturated water sparged into the bottom of the first compartment of the DAF tank. These particles and oils form a froth that floats to the top of water in the DAF tank. The froth is intermittently skimmed off and sent to disposal. The water continues through a series of baffles to the settling compartment where large particles agglomerate and fall to the bottom. These are collected as a sludge at the bottom of the settling compartment and taken off for disposal. Clear water flows from the settling compartment through a sealed weir to a holding basin that is part of the DAF tank.

Clear water is circulated through the DAF tank by the DAF circulation pumps. The circulating water combines with air from the DAF air blowers and enters the DAF air drum which promotes saturation of the water with high pressure air. Saturated water is circulated to the aeration compartment of the DAF tank.

Clear water from the DAF tank holding basin flows by gravity to the sand & activated carbon filter to remove any finely suspended solids and to absorb any remaining pollutants that may be present in the clear water. The filtered clear water flows out the bottom of the filter by gravity into the clear well which serves as a reservoir for produced water by the plant.

High lift pumps move water from the clear well through a large-diameter pipeline to the distant water tower for storage. Produced water destined for the water tower undergoes final treatment at the plant with chlorine and caustic soda. The chlorine ensures a sanitizing environment as the water travels through the municipal distribution system. The caustic soda is added for pH control in order to minimize any corrosion in the distribution system.

Water is pumped out of the water tower by the distribution pumps for usage by the community.