Process Description

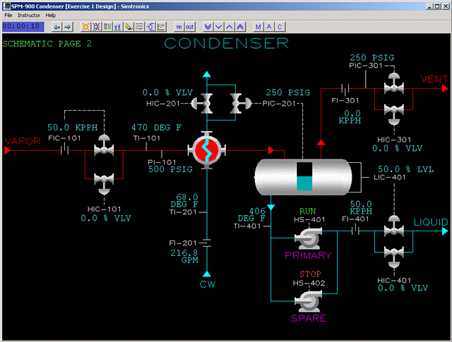

The SPM-900 Condenser Process Simulation can be configured to condense either saturated or superheated steam at a variety of process conditions. The default configuration is to condense saturated steam at 500 PSIG and 470 Deg F to saturated liquid at 250 PSIG and 406 DEG F.

Steam vapor enters a countercurrent tube-and-shell type heat exchanger

on the shell side. cooling water on the tube side is used to condense

the steam. The condensate enters an accumulator, where the condensed

liquid is drawn off by a pump. A vent line is provided to prevent

over-pressuring or for partial condenser operations.

Instrumentation

The vapor feed flow loop is outfitted with a flow controller (FIC-101), a temperature indicator (TI-101) and a pressure indicator (PI-101). The flow control valve has a bypass valve which can be modulated with HIC-101.

Cooling water flow is controlled by accumulator pressure controller PIC-201. A bypass valve (HIC-201) is provided around PCV-201. Cooling water flow rate is indicated by FI-201 and cooling water supply temperature is indicated by TI-201.

Accumulator pressure may also be controlled by PIC-301 which modulates a vent flow line. A bypass valve (HIC-301) is provided around PCV-301. Vent flow rate is indicated by FI-301.

Condensed vapor is pumped out of the bottom of the accumulator. A primary and spare pump are provided. These pumps can be started and stopped with switches HS-401 and HS-402 respectively.

Liquid level in the accumulator is maintained by level controller LIC-401, liquid flow is indicated by FI-401, and accumulator temperature is indicated by TI-401.