The PSU:

- Documents your training

- Provides reports for OSHA 1910.119 requirements

- Allows for self-paced instruction

- Delivers proven methodology for operator certification

- Stimulates competitive spirit

- Provides targets for operators

- Provides recognition for achievement of quantitative goals

- Archives all operator data

- Provides extensive data reportig for instructors

Performance Standards

The SPM Series come with pre-recorded Performance Standards for start-up, shut down, and several troubleshooting scenarios. An instructor may also choose to create their own new exercises and complementary Performance Standards. Trainee’s scores are determined through an objective comparison of their performance to that of the Performance Standard.

Performance Analysis

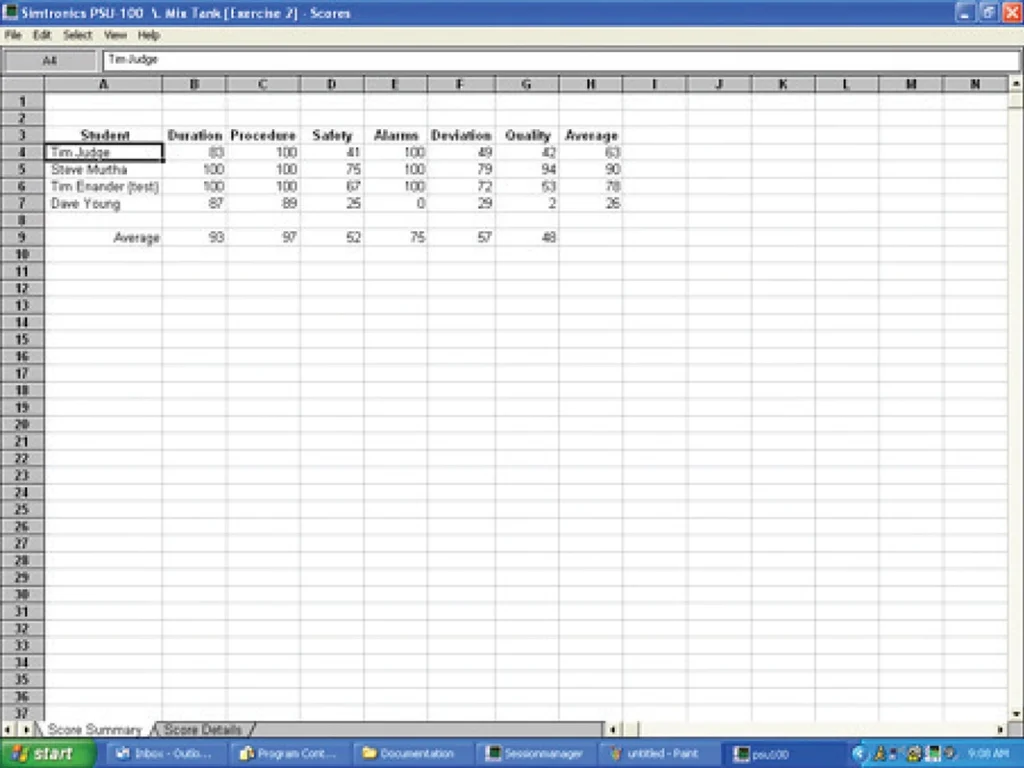

The Simtronics PSU analyzes the collected data for a trainee and/or a group of trainees. An analysis is performed on the data as compared to the performance standard. Scores are generated for the trainee in the following categories:

- Time to Complete Training Exercise

- Adherence to Standard Operating Procedure

- Safety

- Alarms

- Deviation from Design Conditions

- Product Quality

There is a set of data for each Initial Condition in each Process Model. There may be 40 Initial Conditions for Distillation. Each Initial Condition is an exercise. For example: design conditions with feed pump failure, cold start conditions with steam failure, intermediate conditions with upstream composition changes, etc. The DSS automatically records and time-stamps every procedural move made by the trainee. This includes all trends and events, such as changing setpoints, acknowledging alarms, and tuning an instrument. The PSU then analyzes this data and assigns an objective score based on the exercise’s Performance Standard. This data is extensive, but simple and measurable.

System Advantages

- Selection criteria allows you to view simulation runs based on the Standared Process Model (SPM) run, the SPM’s exercise number, date of simulation run, and/or the trainee’s assigned class.

- Create your own exercises and corresponding Performance Standards. This allows you to control the standard operating procedures and the scoring criteria for your trainees.

- Five reports are available—Score Summary, Score Detail, Trend Comparison, Event Comparison, and Notes. Any of these reports can be displayed or printed.

- Report data can be copied to an external program such as a spreadsheet, Training Records Management System (TRMS), or Learning Management System (LMS) using familiar editing commands.

- Compare the scores of several trainees or an entire class using the Score Summary report. Or you can track an individual’s progress as the same exercise is run several times. In one concise report, view multiple simulation runs and their scores on a 0 – 100% scale. The comparison, the graph can be resized to show more detail.