Process Description

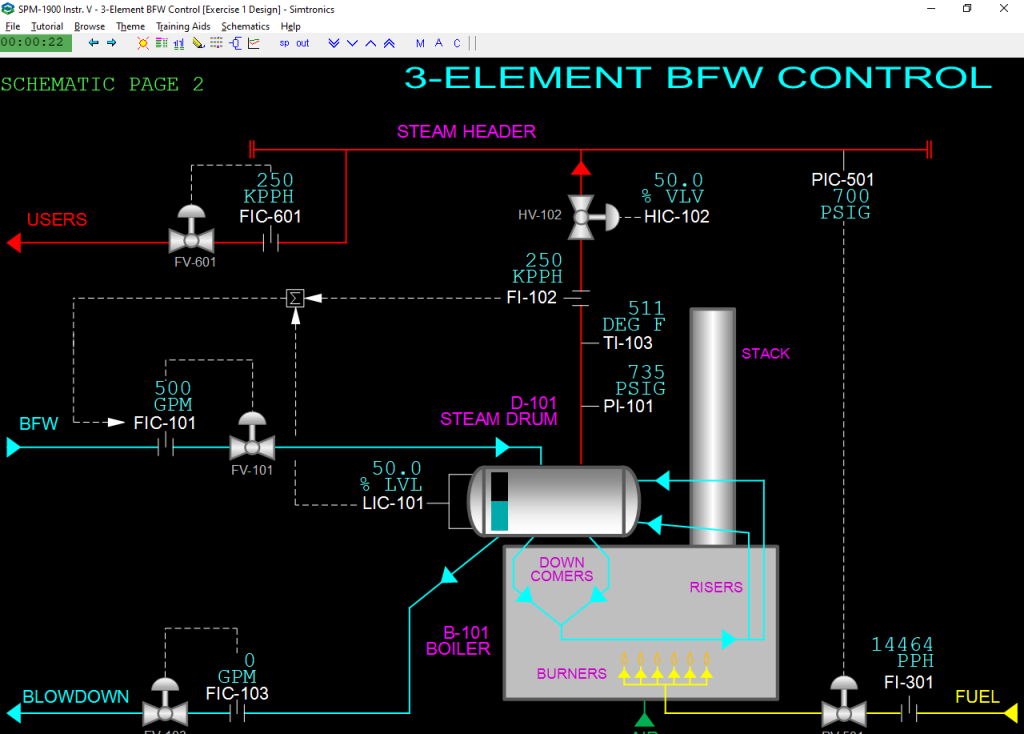

Boiler feed water enters the steam drum. Saturated steam is generated in the risers of the boiler. The saturated steam leaves the steam drum and goes to the steam header. Steam users then draw the steam from the steam header.

Fuel enters the firebox of the boiler where it is automatically ignited and burned. Sufficient air for complete burning is provided. The downcomers and risers are heated both by radiant and convective heat transfer. The hot combustion gases then pass out the stack.

A blowdown line is provided, where water is periodically drawn off to prevent a buildup of minerals and sediment in the boiler.

Instrumentation

Boiler feed water to the steam drum is controlled by flow controller FIC-101. Blowdown is controlled by flow controller FIC-103.

Steam drum pressure is indicated by PI-101 and steam drum temperature is indicated by TI-103. Steam drum level is indicated by LIC-101. Steam rate is indicated by FI-102. The boiler may be isolated from the steam header by HIC-102.

Fuel rate to the boiler is indicated by FI-301.

Steam header pressure is controlled by PIC-501. Steam demand is controlled by FIC-601.