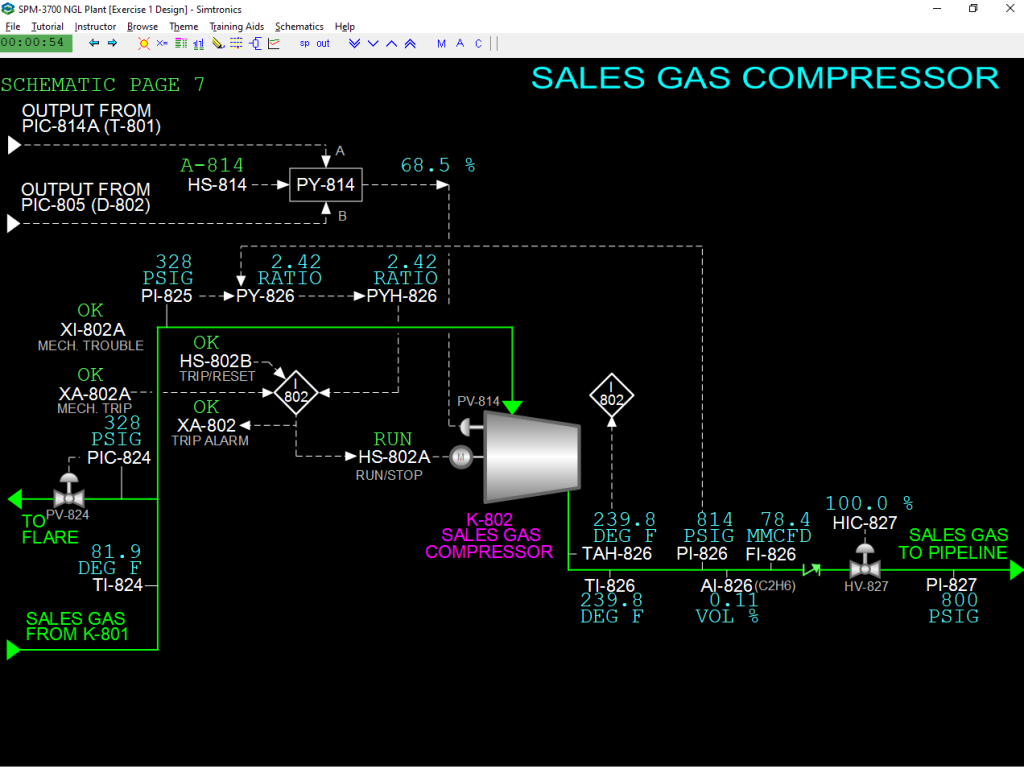

Process Description

The Gas Compression Plant consists of multiple centrifugal compressors. Each centrifugal compressor will have the following characteristics. Gas passes through a suction valve before entering the suction drum. If the process gas demand is less than the minimum recommended compressor flow (surge point), then the makeup gas will mix with the kickback flow. The gas then passes through a cooler, where the temperature is lowered to prevent excessive compressor discharge temperatures. Any condensate present in the gas will be knocked out in the suction drum before the gas enters the compressor. The compressed gas is then drawn off from the discharge side of the compressor by users. In the event of a decrease in process gas demand by the users, a minimum compressor flow line (kickback or spillback) is provided to allow the recycling of gas to prevent compressor surging. A vent/flare line is also provided to prevent an over pressuring of the system.