Process Description

Gas pipelines are used to transport gases such as natural gas from supply sources over long distances to users of the gas. In SPM-3910, the pipeline gas is natural gas (mainly methane) and is supplied from two sources at the beginning of the pipeline system. The flow rate and pressure of each supplier is variable and not under direct control of the pipeline operator except by isolation using an emergency shutdown switch.

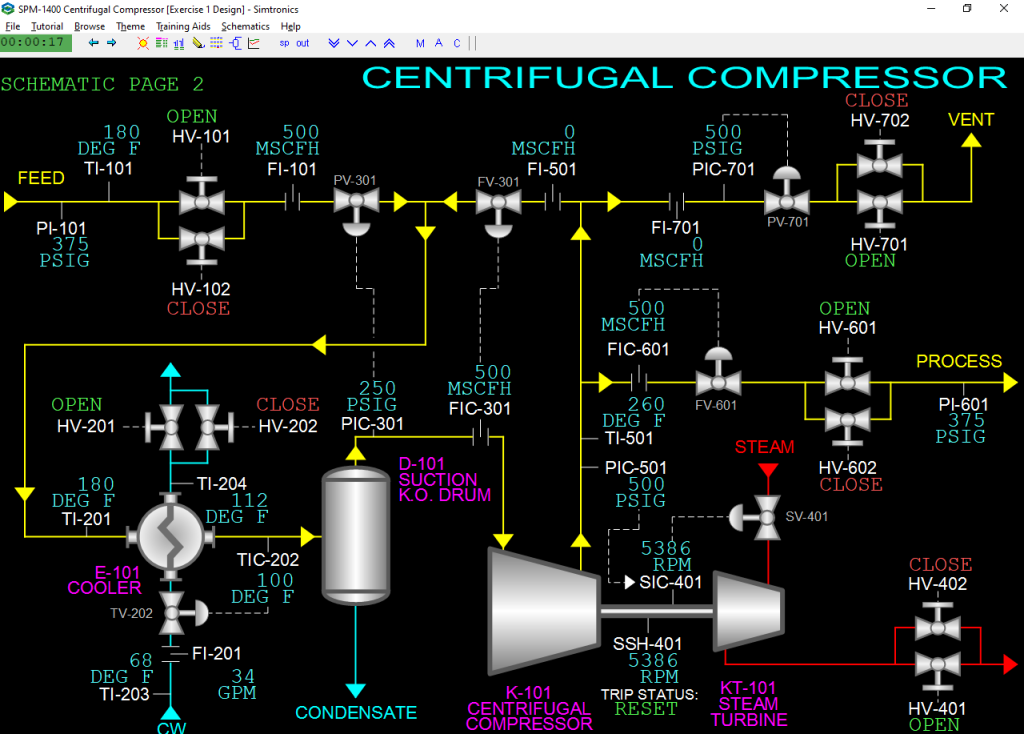

The supply gas is transported over a long pipeline segment to Compressor Station No. 1 in order to increase the pressure of the gas so it will continue flowing through the next pipeline segment. The booster compressors are centrifugal type with electric motor drive.

Compressor Station No. 1 can be bypassed in case the compressor station needs to be isolated for maintenance. Interlock logic prevents bypassing the station unless no compressors are operating. The compressor station includes equipment to remove liquid slugs from the gas before compression and to filter the gas to remove any solid particulates.

The control system includes the ability to regulate either the inlet or outlet pressure from the compressor station.

The gas pipeline system contains one more compressor station which operates identically to Compressor Station No. 1. The two compressor stations are separated by a very long pipeline segment. Users take flow off the pipeline downstream of Compressor Station No. 1 under flow control. Like suppliers, the pipeline operator does not have direct control of the flow rate to each user except by isolation using an emergency shutdown switch. The final user takes flow off under pressure control at the end of the last pipeline segment.

Program Features

SPM-3910 is preconfigured with a number of exercises where the pipeline operation is relatively balanced and then supply and/or demand changes over time. The operator will need to assess the situation and determine if a change in the operating compressors, control setpoints or supplier/user isolation is needed to keep the pipeline operating safely.

The following instructor features allow SPM-3910 operating conditions to be set up to reflect typical pipelines if so desired:

- Adjustable battery limit conditions

- Adjustable length and diameter of each pipeline segment

- Adjustable compressor characteristics

Additionally, SPM-3910 is engineered with wide instrument ranges on pressure and flow controllers to allow operation at desired process conditions.