Process Description

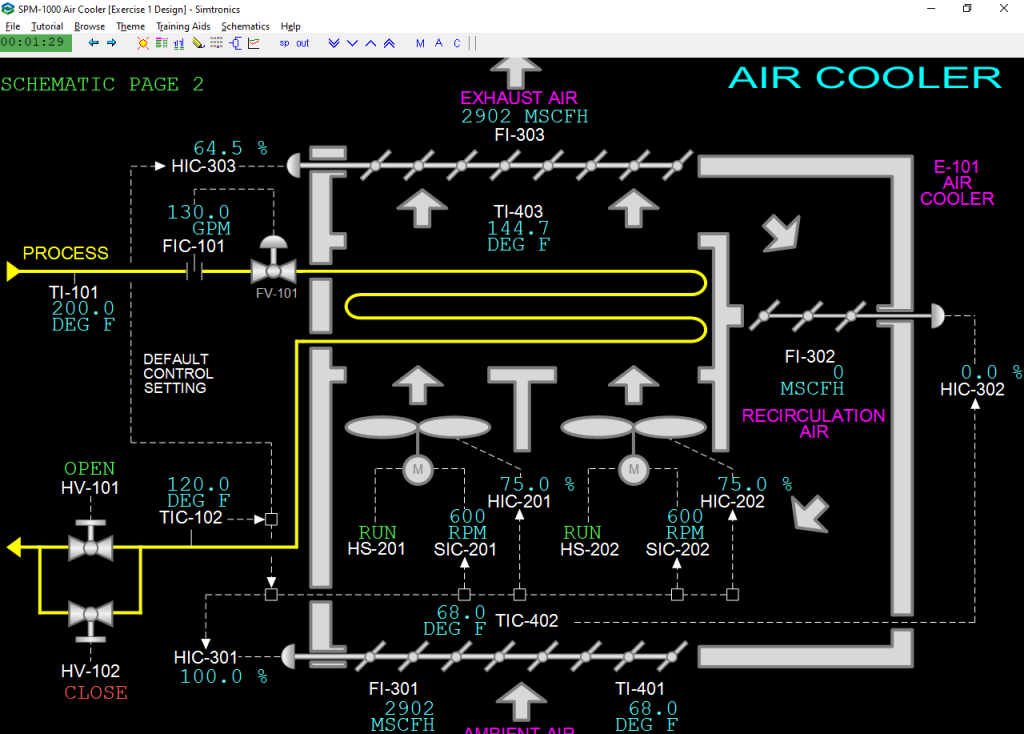

The SPM-1000 Air Cooler Process Simulation can be configured to operate as a conventional air cooler, where the air side of the heat exchanger is completely open to the atmosphere. For handling of process fluids that congeal or freeze at temperatures above the winter ambient temperature, the air cooler has been provided with a recirculation system to maintain air temperature entering the tube bundle at a sufficiently high level to prevent congealing or freezing of the process fluid.

For close control of process fluid outlet temperature, the air cooler has been provided with top and bottom louver position controls, auto-variable-pitch fan hubs, and variable-speed fan motors.

The default configuration for the air cooler is as follows. The fan speed and fan blade pitch are maintained constant. The bottom louvers are maintained completely opened. The top louvers are under process outlet temperature control.

Instrumentation

The process flow loop is outfitted with a flow controller (FIC-101) and block valves that can be opened and closed with switches HV-101 and HV-102. All the valves have linear flow characteristics. Inlet process temperature is indicated by TI-101 and outlet process temperature is controlled by TIC-102.

Each fan is provided with a start/stop switch (HS-201 and HS-202 respectively), speed control (SIC-201 and SIC-202 respectively), and fan blade pitch control (HIC-201 and HIC-202 respectively).

The inlet air louver position is controlled by HIC-301, the outlet air louver position is controlled by HIC-303, and the internal air recirculating louver is controlled by HIC-302.

Inlet air flow is indicated by FI-301, outlet air flow is indicated by FI-303. Recirculating air flow is indicated by FI-302.

Ambient air temperature is indicated by TI-401, inlet air temperature is indicated by TIC-402, and outlet air temperature is indicated by TI-403.