Process Description

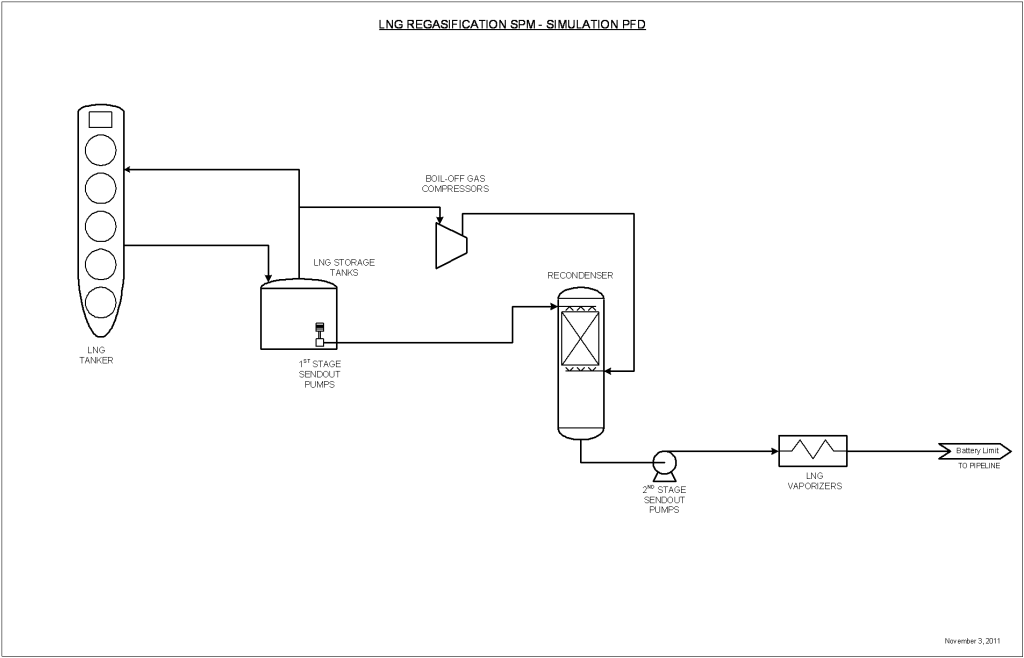

Liquefied natural gas (LNG) at atmospheric pressure is offloaded from an LNG Tanker via submerged pumps and sent to one of two LNG Storage Tanks. During tanker unloading any vapor that is displaced in the tanks is returned to the LNG Tanker to maintain atmospheric pressure in the tanker’s storage vessels.

LNG from the Storage Tanks is pumped out by the 1st Stage Sendout Pumps that are submersed in the LNG. The LNG is sent to the Recondenser to absorb any LNG vapors produced from the LNG Storage Tanks. Because LNG stored at near-atmospheric pressure is very cold, the walls of the tanks will pass heat from the atmosphere despite being well-insulated. This so-called heat leak will result in the vaporization of some of the LNG in the tanks. The vapor from an LNG Storage Tank is compressed by its Boil-Off Gas Compressor and sent to the Recondenser for contacting with LNG pumped from the Storage Tanks.

The Recondenser is a column containing a packed bed of rings to permit intimate contacting of the compressed vapors from the Storage Tanks with LNG pumped from the Storage Tanks. The Recondenser operates at a pressure high enough to cause the tank vapors to be recondensed into the LNG from the storage tanks. This causes the LNG temperature to rise depending on the flow ratio of tank vapor to pumped LNG. LNG accumulates at the base of the Recondenser and is sent to the 2nd Stage Sendout Pumps.

The 2nd Stage Sendout Pumps increase the LNG pressure high enough so it can be sent to a natural gas pipeline. The pressurized LNG is vaporized in the LNG Vaporizers. Three types of LNG vaporizers can be employed:

- Open-rack sea water vaporizer

- Submerged combustion vaporizer

- Shell and tube vaporizer using warm glycol

The vaporized LNG is sent to a pipeline at the battery limit